- BSPD BEARINGS...Machine Element

- FOR IMMEDIATE ACTION E-MAIL info@bspd-bearing.com

-

Products

Catalog

- Ball Bearings

-

Slewing Bearings

- Interchange Series - Ungeared

- Interchange Series - External gear

- Interchange Series - Internal gear

- Kaydon Slewing Bearings

- Metric Size Slewing Rings

- Inch Size Slewing Rings

- Metric Size Slewing Rings (2)

- IMO Slewing Rings & Slewing drives

- SKF Slewing Bearings

- INA Slewing Bearings

- Franke Slewing Bearings

- Needle Roller Bearings

- Crossed Roller Bearing

- Spherical Roller Bearings

-

Tapered Roller Bearings

- Inch Single Row Tapered Roller Bearings

- Metric Single Row Tapered Roller Bearings

- Single row tapered roller bearing with flanged outer ring

- Double row tapered roller bearings& TDO design

- Double row tapered roller bearings& TDI design

- Tapered roller bearings& single row& matched back-to-back

- Tapered roller bearings& single row& matched face-to-face

- Four-Row Tapered Roller Bearings

- Cylindrical Roller Bearing

- Linear Bearing

Bearings & Components

-

Stainless Steel Bearings

- Stainless Steel Angular Contact Ball Bearings

- Stainless Steel Ball Bearings

- Stainless Steel Balls

- Stainless Steel Mounted Units, Pillow Blocks, Housed Unit Bearings & Inserts

- Stainless Steel Self Aligning Ball Bearings

- Stainless Steel Spherical Plain Bearings and Rod Ends

- Stainless Steel Thrust Ball Bearings

- Stainless Steel V-Groove Guide Wheels

- Ceramic Bearings

- Polyurethane Wheels

Special Material

- About BSPD

- Contact Us

- Request A Quote

-

- info@bspd-bearing.com

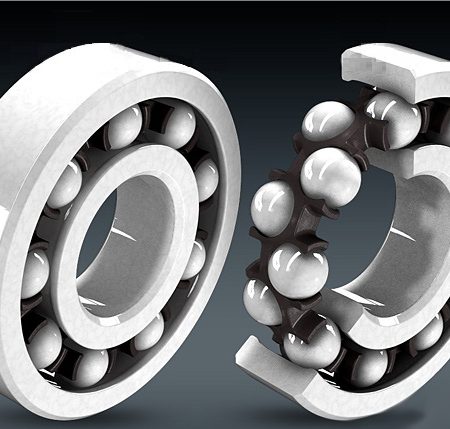

Ceramic Bearings

-

Ceramic Deep Groove Ball Bearings

In the development and application of engineering ceramic products, ceramic ball bearings are an example of the wide application of engineering ceramics in the industrial field and have received great attention from many countries. In high-speed precision equipment, fully mixed ceramic ball bearings are used, that is, the use of rolling elements. Hot pressing Si3N4 ceramic balls, the ring is still a ring. This kind of bearing has a high installation habit, small modification of the machine tool structure, easy maintenance, and is especially suitable for operating occasions. Its high-speed assembled electric vehicles have high-speed, high-speed motion and bearing rings. High power, long life and other advantages -

Ceramic Angular Contact Ball

Ceramic angular contact ball bearing divided into full ceramic and hybrid ceramic bearing. Full ceramic angular contact ball bearing’s characters are the high temperature resistance up to 1200 centigrade degree and working under different extreme severe environment. Having the highest rotating speed is the major specialty of hybrid angular contact bearing. The dental angular contact ceramic ball bearing we developed can reach to 350,000RPM. -

Ceramic Self Aligning Bearings

Self Aligning Ceramic Bearings have high temperature resistance, low cold resistance, high-pressure resistance and corrosion resistance, but have no magnetism and power insulation and oil lubrication. They are suitable to be used in special environments where mixed ceramic ball bearings and steel bearings cannot work. With high corrosion resistance, these bearings can be used for a longer time in corrosive environments, including most acid, alkali and solvent environments. -

Ceramic Thrust Ball Bearings

Full ceramic thrust bearing material: Both thrust washer and ball are ceramic material which including ZrO2, Si3N4 or SiC.Hybrid ceramic thrust bearing material: Thrust washer material can be chrome steel or stainless steel. Ball is ceramic which can be ZrO2, Si3N4 or SiC. Inner diameter range of Ceramic thrust ball bearing from 3mm to 120mm, finished grinding raceway included. Production model have 511 series etc various ceramic thrust bearing. -

Ceramic Balls

Ceramic balls are spherical, rolling elements that provide higher stiffness, lower thermal expansion, lighter weight, increased corrosion resistance, and higher electrical resistance than steel balls. They are made from a variety of ceramic materials.