- BSPD BEARINGS...Machine Element

- FOR IMMEDIATE ACTION E-MAIL info@bspd-bearing.com

-

Products

Catalog

- Ball Bearings

-

Slewing Bearings

- Interchange Series - Ungeared

- Interchange Series - External gear

- Interchange Series - Internal gear

- Kaydon Slewing Bearings

- Metric Size Slewing Rings

- Inch Size Slewing Rings

- Metric Size Slewing Rings (2)

- IMO Slewing Rings & Slewing drives

- SKF Slewing Bearings

- INA Slewing Bearings

- Franke Slewing Bearings

- Needle Roller Bearings

- Crossed Roller Bearing

- Spherical Roller Bearings

-

Tapered Roller Bearings

- Inch Single Row Tapered Roller Bearings

- Metric Single Row Tapered Roller Bearings

- Single row tapered roller bearing with flanged outer ring

- Double row tapered roller bearings& TDO design

- Double row tapered roller bearings& TDI design

- Tapered roller bearings& single row& matched back-to-back

- Tapered roller bearings& single row& matched face-to-face

- Four-Row Tapered Roller Bearings

- Cylindrical Roller Bearing

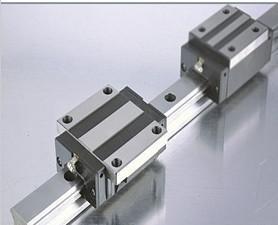

- Linear Bearing

Bearings & Components

-

Stainless Steel Bearings

- Stainless Steel Angular Contact Ball Bearings

- Stainless Steel Ball Bearings

- Stainless Steel Balls

- Stainless Steel Mounted Units, Pillow Blocks, Housed Unit Bearings & Inserts

- Stainless Steel Self Aligning Ball Bearings

- Stainless Steel Spherical Plain Bearings and Rod Ends

- Stainless Steel Thrust Ball Bearings

- Stainless Steel V-Groove Guide Wheels

- Ceramic Bearings

- Polyurethane Wheels

Special Material

- About BSPD

- Contact Us

- Request A Quote

-

- info@bspd-bearing.com

Linear Motion Guides

-

THK Global Standard Caged Ball LM Guide (SHS)

The advantages are as follows: can move briskly without gaps, allow large loads, and improve walking accuracy -

THK Global Standard LM Guide (HSR)

The four functions (shape, reverse and lateral direction) in the direction of the THK linear guide all have the same Japanese design. Each row of steel balls is arranged at a contact angle of 45°. It can not only maintain the low friction section of the surface, but also strengthen the three-dimensionality in 4 directions. At the same time, due to the low surface height and the highly invisible design of the LM etc., it is able to move steadily. -

THK Miniature Caged Ball LM Guide (SRS)

THK miniature antenna type SRS-M series guide rail: retainer THK guide rail-SRS, with less balls, anti-rust, features, etc. -

THK Miniature LM Guide

Advantages The track section height is low, and it is a THK track with a lightweight and three-dimensional structure. -

THK Radial Type Caged Ball LM Guide (SSR)

Advantages: 1 low noise and good sound quality 2Excellent high speed, long life 3 does not require long-term maintenance -

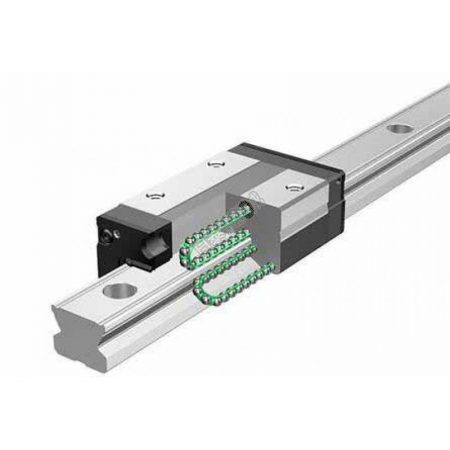

THK Radial Type LM Guide (SR)

[Miniaturization, heavy load] Because the miniaturized design type with low section height has a steel ball contact structure with strong load-bearing capacity in the radial direction, it is suitable for horizontal guides. [Easy to achieve installation accuracy] This type is a self-aligning type, which is easy to absorb the parallelism and horizontal accuracy errors between the two axes, so as to achieve smooth linear motion. 【Low noise type】 The revolving part of each steel ball row is designed to pass through the guide part of the LM slider ball returner, so that the steel balls can circulate smoothly, so low-noise movement can be achieved. [Excellent durability] Even under the action of preload or offset load, the differential sliding amount of the steel ball is restrained to the limit, realizing the long-term maintenance of high damage and accuracy. [Stainless steel type is also available] -

THK Separate Type (GSR)

The steel ball rolls along the LM track and the LM along the 2 rows of rolling surfaces that have been precisely ground; the end cover at the upper end of the LM allows the LM steel stepping plate to hold the steel ball, so the steel ball will not fall off. Due to the inclination of the top surface of the LM, it is possible to simply remove and obtain proper preload by fixing the LM with equipment. The GSR type adopts a special contact structure with an arc-shaped arc, so it has automatic centering capability and is most suitable for places where high installation is not easy and general industrial machine tools. -

THK Separate Type (HR)

The steel balls roll along the LM rail and the two rows of rolling surfaces on the LM block that have been precisely ground; the end cover plate assembled on the LM block makes the rows of steel balls circulate. The LM block uses a retaining plate to hold the steel ball, so the steel ball will not fall off. The angular contact structure is adopted, and the two rows of steel balls rolling on the LM track are in 45 angular contact with the rolling surface. Therefore, after assembling a set on the same plane (combining two LM rails and LM blocks used on the same plane), the same load can be carried in 4 directions (radial, reverse radial and lateral) Load. Moreover, since the section height is low, a compact and stable linear guide mechanism can be obtained. In addition, the gap adjustment is relatively easy, and the installation error absorption capability is also excellent.